There are a number of modifications that can be installed in the Cargo Bay, one being a convenience feature, and four being material processing units (hereby referred by their acronym, MPUs). MPUs process ore chunks into a powdered form. allowing them to be stored internally as processed ore, removing their volume from the cargo bay, but at the cost of not converting the chunk into powder with the 100% efficiency of Enceladus. Most MPU models also provide remass recovery, allowing part of the water content of an ore chunk to be put into the propellant tank of the ship.

MPUs will not process anything that isn't an ore chunk or ringroid that enters the bay, regardless of their volatility or mineral content (lifepods, dead bodies, spent mass driver rounds, serenity torbernite crystals, etc.)

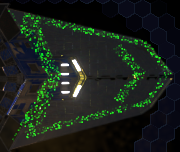

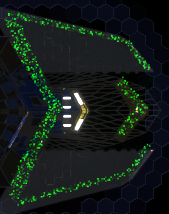

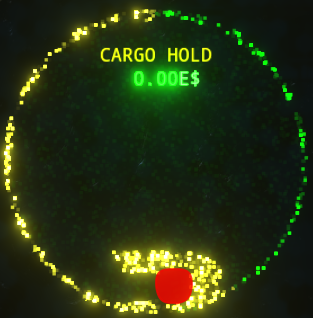

The galleries for the MPUs will have the roughly-approximate processing areas marked in red. Any ore chunks in these areas will be processed.

Bare Bay Upgrades

Cargo bay baffles

Price: 2,000 E$

Mass: 400 kg

These spring-mounted cargo bay baffles prevent accidental loss of cargo during deceleration.

Springed baffles open inwards only, but may be held open by objects when the bay is very full. Some of the very wide or odd excavator designs host a solid barrier instead of baffles.

User Manual

These spring-mounted cargo bay baffles prevent accidental loss of cargo during deceleration.

Gallery

Mineral Processing Units (MPUs)

Rusatom-Antonoff MPU

Price: 350,000 E$

Processing capacity: 20 kg/s Power draw: 2 MW / chunk Mineral processing efficiency: 40% Remass processing efficiency: 40% Mass: 1,700 kg Manufacturer: Rusatom-Antonoff

The Rusatom-Antonoff Mineral Processing Unit uses reactor heat to sublimate water content out of a large cargo volume, so that mineral content can be collected and stored. Evaporated water is collected via a cryo-ring, and can be reprocessed into propellant. This MPU boasts minimal power consumption and excellent processing reach, but the heating process is inefficient, and much of the cargo and water is lost during processing.

User Manual

Converts ore chunks into processed ore. Replenishes propellant. Requires ore to be in the processing chamber. Processes multiple ore chunks simultaneously. Power requirements and processing speed listed per chunk. Processed ore stored in separate containers, with capacity limited per mineral type.

Gallery

Nakamura MPU

Price: 500,000 E$

Processing capacity: 50 kg/s Power draw: 25 MW / chunk Mineral processing efficiency: 70% Remass processing efficiency: 30% Mass: 4,200 kg Manufacturer: Nakamura Dynamics

Nakamura Dynamics' Mineral Processing Unit uses microwaves to sublimate the ice out of cargo and stores it in compact containers. Evaporated water is collected via a cryo-ring, and can be reprocessed into propellant.

User Manual

Converts ore chunks into processed ore. Replenishes propellant. Requires ore to be in the processing chamber. Processes multiple ore chunks simultaneously. Power requirements and processing speed listed per chunk. Processed ore stored in separate containers, with capacity limited per mineral type.

Gallery

Mitsudaya-Starbus MSU

Price: 900,000 E$

Processing capacity: 100 kg/s Power draw: 150 MW / chunk Mineral processing efficiency: 90% Remass processing efficiency: n/a Mass: 2,500 kg Manufacturer: Mitsudaya-Starbus

The Mitsudaya-Starbus Mineral Smelting Unit is made for efficient mineral processing, regardless of the energy cost. It uses a combination of laser-cutting and directed microwave beams to efficiently disassemble any mineral chunk. Remass recovery is not available in this unit.

User Manual

Converts ore chunks into processed ore. Requires ore to be in the processing chamber. Processes multiple ore chunks simultaneously. Power requirements and processing speed listed per chunk. Processed ore stored in separate containers, with capacity limited per mineral type.

Gallery

Voyager RSLS Fabrication Plant

Price: 1,500,000 E$

Processing capacity: 40 kg/s Power draw: 20 MW / chunk Print power draw: 70 MW Printing capability: drones, ammunition Mineral processing efficiency: 50% Remass processing efficiency: 60% Mass: 6,000 kg Manufacturer: Nakamura-Obonto

Designed for long range research vessels, the Voyager fabricator sacrifices cargo space to fit a fabricator inside the cargo bay, with a series of cryo-rings providing excellent propellant reclamation. This combined Mineral Processing / Rapid Selective Laser Sintering Unit by Nakamura Dynamics and Obonto Micro Engineering can resupply vanadium-hardened iron ammunition, or disposable nanodrones that use a platinum mirror array in an iron frame.

User Manual

Converts ore chunks into processed ore. Replenishes propellant. Requires ore to be in the processing chamber. Processes multiple ore chunks simultaneously. Power requirements and processing speed listed per chunk. Processed ore stored in separate containers, with capacity limited per mineral type. Produces kinetic ammunition from a 9:1 ratio of iron to vanadium. Produces nanodrone components from a 4:1 ratio of iron to platinum.

Gallery

Tuning

The cargo bay also has the option to adjust the internal microseismic scanner's focus from -100 to 100 units in sets of 10. This adjusts the side and quality that the bay is scanned. The default focus of 0 covers the entire bay with a decent scanning resolution, a focus of 100 or -100 will cover the top or bottom (respectively) quarters of the bay with a very high resolution. Values inbetween will have the resolution skewed between the top and bottom of the bay.

|

|

|

|

|

| Focus of -100 | Focus of -50 | Focus of 0 | Focus of 50 | Focus of 100 |